| |

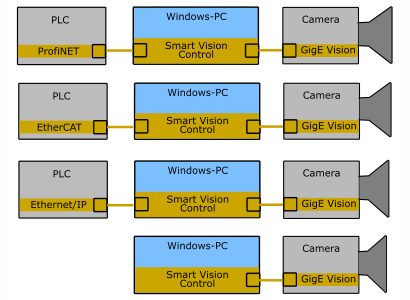

SmartVision with direct fieldbus connection

- Real-time image acquisition

- Simple image pre-processing

- Image processing without programming

- Comprehensive SmartProcessing

- Speed AutoAdjust

- Scaling (semi-automatic)

|

|

|

|

Fieldbus connection to:

- Profinet

- EtherCAT

- Ethernet/IP

|

| |

Use with:

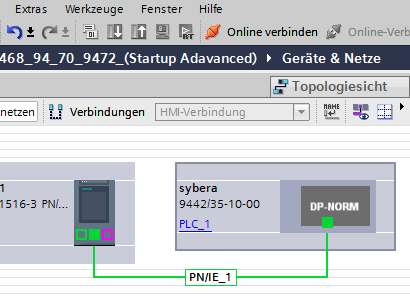

- Siemens TIA Portal

- Rockwell Studio 5000

- Beckhoff TwinCAT

a.o.

|

|

|

|

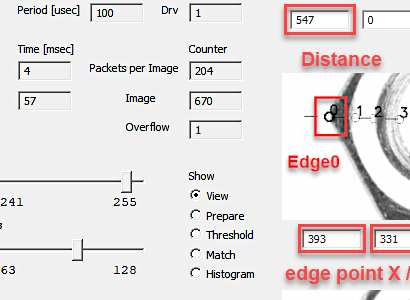

Smart Image Processing:

- Position determination

- Angle determination

- Distance measurement

- Contour measurement

- Corner position determination

- Pattern matching

|

| |

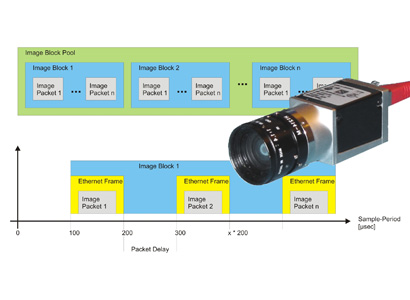

Real-time image acquisition

|

|

|

|

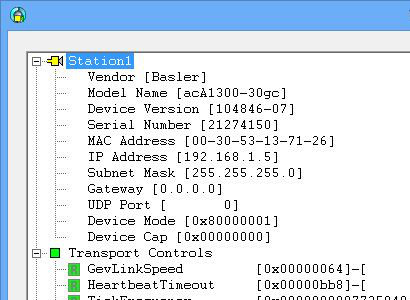

GenICAM Configurator with Diagnostics

|

Typical Applications

|

| |

- Pick & Place

- Assembly

- Inspection

- Quality Assurance

- Packaging

- Metrology

- Welding Technology

|

|

Worth Knowing ...

|

GigE Vision Camera System

|

The smart vision solution with direct fieldbus connection requires no additional hardware – only a Windows PC and a GigE Vision camera (e.g., Basler). Parameterization instead of programming: simple image pre-setting and image processing without programming knowledge.

This product from SYBERA combines the fieldbus connection (Profinet, EtherCAT or Ethernet/IP) to the PLC and image acquisition as well as image processing. Tasks such as Pick&Place, metrology, and quality assurance can be realized with minimal effort. The camera integration is done via the additional program VisionGen.

Besides the camera, lens, and lighting, image pre-processing plays a crucial role for the quality of the results (brightness, contrast, sharpness, threshold).

A total of ten image processing elements (Items) are available, which can be freely combined and transmit the result directly to the PLC: Center point determination, angle determination, distance measurement, contour measurement, corner position determination, and pattern matching.

|

| |