| |

| |

- Intelligent Station Management

- High Precision Reatime Control

- Station Cycles upto 250 μsec

- Cyclic Data Exchange

- ProfiNET Diagnostics

- ProfiNET acyclic Service Interface

- ARP, DCP, RPC, LLDP Implementation

- Error Management

- GSDML Station Configuration

|

|

Typical Applications

|

| |

- Assembly

- Packaging

- Embossing Technique

- Service

- Meassurement

- Welding

|

|

Video Coach

|

|

|

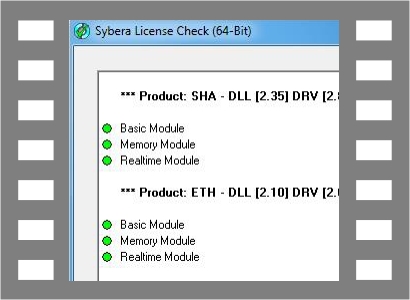

Video: ProfiNET Simulator Installation |

| |

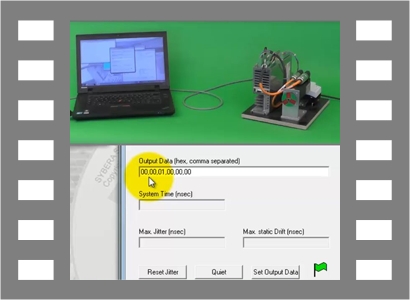

Video: ProfiNET Simulator Configuration |

|

ProfiNET Master Simulator for Windows

|

|

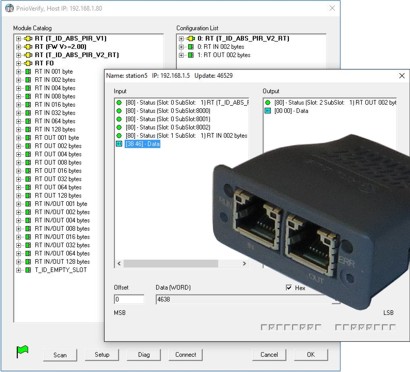

The SYBERA ProfiNET Master Simulator PNIOVERIFY allows the control of ProfiNET IO devices at realtime, on a standard PC, without the need

of additional controller hardware. The PROFINET control can be realized simply by the PC with a standard Ethernet adapter.

The Master Simulator is based on the high precision XRealtime Engine for sending and receiving of ProfinetIO frames at realtime.

The Master Simulator allows the handling of ProfiNET-IO data without the need of any complex ProfinetIO management. The Master Simulator

scans the bus for Accesspoints, and offers simply configuration of functional modules. Also diagnostics can be handled easily.

|

ProfiNET Master Simulator Functionality

|

|

The Ethernet fieldbus communication differs not only by a different protocol specification, but also by the bus

topology. So realized e.g. EtherCAT a line topology, while ProfiNET implements a star topology. While ProfiNET

implements the typical master / device principle between controller and devices, PROFINET consists of a provider /

consumer model in which the roles can be swapped. However, PROFINET realtime communication requires a defined master /

device relationship. Similar to ProfiNET, SYBERA also speaks of a PROFINET master in the new PROFINET stack. The new

real-time PROFINET master from SYBERA eliminates the need for a separate controller hardware, since the PROFINET

controller can be implemented by the PC with standard Ethernet adapters. The PROFINET Master is offered by SYBERA as an

open real-time library system and enables the developer to program a deterministic control for PROFINET devices.

|

ProfiNET Master Simulator Technology

|

|

Due to the increasing networking of the industrial environment, the Ethernet communication plays an increasingly

important role in the connection and control of devices. Today, various Ethernet standards are available for fieldbus

communication, including: a. SERCOS, Powerlink, ProfiNET and PROFINET. The communication principle is typically based

on a deterministic process data exchange and therefore requires deterministic software and hardware for control and

device. Direct control of the fieldbus devices with a PC and the Windows operating system was only possible with the

introduction of so-called real-time expansion systems. An example of this is the SYBERA real-time extension, which

enables Ethernet update cycles of up to 250 μsec.

|