| |

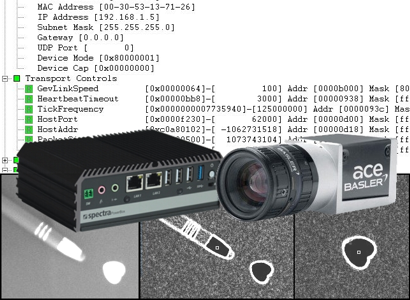

- Industrial-PC with Windows IoT

- GigE Vision Camera

- Fieldbus Interface

- Real-time Image Acquisition

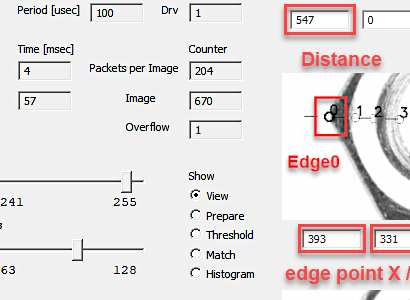

- Image Processing without Programming

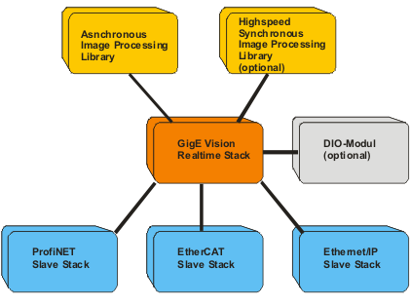

- Asynchronous Image Processing

- Synchronous Image Processing (optional)

|

|

|

|

-

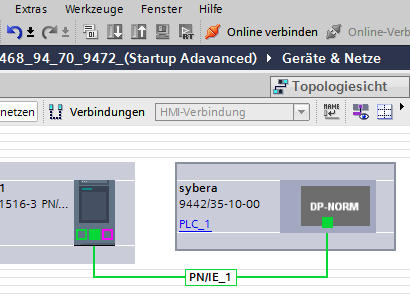

Fieldbus interface for ProfiNET, EtheCAT and Ethernet/IP

|

| |

Use with Siemens TIA-Portal, Rockwell Studio 5000, Beckhoff TwinCAT, u.a. |

|

|

|

Image smart processing or with programming library |

| |

Image acquisition and Image processing at real-time

|

|

|

|

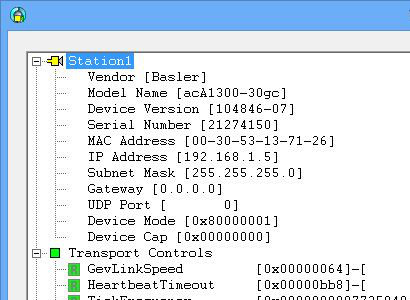

GenICAM configuration and diagnostics |

| Typical Application |

| |

- Control

- Assembly

- Inspection

- Testing technology

- Measure technology

- Packaging

- Soldering

- Sensors

- Monitoring

|

|

FieldboxCAM - GigE Vision Camera System

|

|

The FieldboxCAM SmartCamera system offers a modular principle for image processing and fieldbus connection.

The image is acquisitioned using the GigE Vision standard. The image processing is implemented on a PC.

With the integrated smart processing module, image processing is implemented without programming. Extensive

functions (center, contour, pattern match, edge, distance) are available for this purpose. In addition,

the functions can be expanded with image processing libraries such as OpenCV or SIMD. The fieldbus connection

can be made with ProfiNET, EtherCAT or Ethernet/IP. The configuration of the FieldboxCAM is created with the

GenICam configurator.

|

|

FieldboxCAM - Functionality

|

|

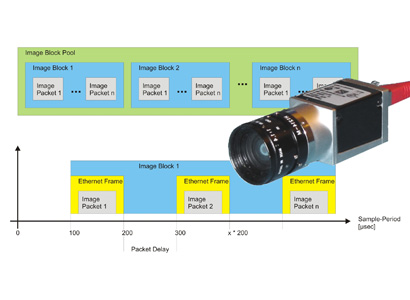

GigE Vision is the interface standard for industrial image processing. It enables industrial cameras to be easily

connected to existing network systems by using Gigabit Ethernet. The GigE Vision Standard consists of four elements:

The GigE Vision Control Protocol (GVCP uses UDP) defines how a device is to be addressed and specifies data channels

and mechanisms for the transmission of images and configuration data between PC and camera. The FieldboxCAM is based

on the X-Realtime Engine from Sybera and thus enables deterministic bid acquisition as well as deterministic image

processing. The FieldboxCAM enables the developer to perform deterministic image processing in connection with other

fieldbus systems. The developer has the option of programming the cameras using simple functions and graphically

designing his own vision applications.

|

|

FieldboxCAM - Technology

|

|

The FieldboxCAM meets the requirements of the

GigE Vision Specification 2.0 and is designed as an open programming

system. In particular, great importance was attached to the critical GVSP protocol timing from GigE. This is done

through image acquisition in real time and the integrated bandwidth control. The system is based on 4 real-time tasks,

for sending and receiving Ethernet frames, and functional processing for cyclic data exchange. The tasks are

functionally synchronized via a STATE machine. A real-time error task detects frame errors and hardware latencies.

With the help of a frame filter, the acyclic GVCP vision frames are separated in real time and transferred to a

telegram stack. SYBERA uses the "Dynamic Jitter Compensation" method with active and passive feedback in the master

libraries.

|